New Paradox A-Cat in Detail: Dario Valenza Interview

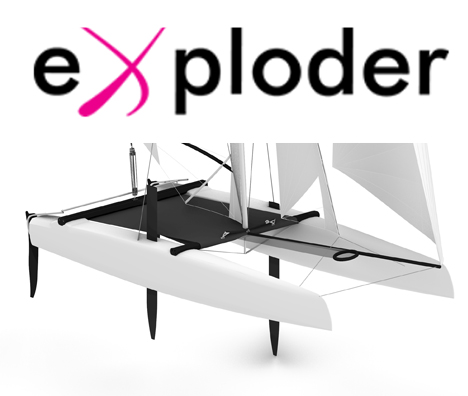

New ACat from Australian based Carbonic Boats. And yet another racing cat designed by Martin Fischer. Seems Martin is quite busy these days on many projects, several of them featuring his S dagger / L Rudders setup.

Dario Valenza, head of Carbonic Boats give us an insight on this new A. Beyond the quite open development the class has shown, compared to the F18 more restricted rules as reference, that the boat alone is not the game decider, and many different designs like the Nikita, Vision, DNA, Scheurer and others are capable to offer you a winning platform. The only new recent boat that has failed in their first and only appearance is Fischer Mayfly. But Dario Valenza is still confident on this setup for the As, and he says the boats is not intended to fly as a main goal.

So another interesting design bet, and as I always remark having people like Dario & Fischer pushing the limits it is a long term benefit for the entire multihull community. Time will say when this new concept will reach an optimiun refinement state, and for a project registered and stamped with an ISAF AClass sticker , that will only be achieved while Racing.

For more info contact Dario at carbonicboats.blogspot.com

——————————————-

– CSN: How did the Paradox project started?

Dario Valenza: As is often the case it was the combination of a number of things. I had always had an interest in the A Class as it is a very elegant rule with few restrictions that are very effective at striking a balance between development and integrity of the fleet.

In particular the limitations on sail area, beam and weight mean that the basic parameters are very similar between different designs so development is all about efficiency.

However up until recently I could not identify an opportunity to take a significant step ahead and create a product that would offer measurable gains to the customer.

My involvement in the America’s Cup brought me into closer contact with the world of multihulls and in particular gave me the opportunity to develop a relationship with Martin Fischer.

As it happened we are both sitting this cycle out but that opened the door to other fascinating and relevant projects.

The decision to go ahead with the project and commit to significant investment in tooling and prototypes was the combination of having a team that I am 100% confident in, having the time to develop the product properly and having identified a real step forward in development. Some strategic aspects also helped such as our location in Australia and our in house machining capabilities.

– Describe the foil solution of the Paradox

DV: The brief to Martin Fischer was to find the best configuration of hull and foils around the track in the widest range of racing conditions.

This means the lowest drag package upwind and downwind with the express requirement that the configuration be stable in pitch and ride height in those conditions when stability allows you to push harder more safely.

Foiling was not a goal and no compromises were made in order to be able to fully foil.

Martin Fischer found that above a certain speed the foils will take all the weight but that is incidental. What matters is that the take-up will be automatic, keeping the boat controllable and level.

The foils use a double S curvature and the rudders use an L shape with the bottom part not quite horizontal.

The top part of the foils curves outboard so that when the foils are fully down the tips move out.

This means that upwind, when the foils are fully down, they are basically vertical.

At upwind speeds, hull drag is less than foil drag so we don’t want to waste any lift (lift has a cost in terms of drag) in the vertical direction. Instead the foils just make very efficient sideforce generators.

When pulled up to the reaching position the tips move inboard right to the innermost point allowed by the rule.

Thus horizontal projected area is maximised and the foils pull up as much as possible.

However the maximum curvature is just under the hull. If the boat starts rising, the part of the foil left in the water becomes more vertical and vertical lift consequently decreases. The inverse curve toward the tips of the foils provides a negative feedback to stabilise ride height.

However the maximum curvature is just under the hull. If the boat starts rising, the part of the foil left in the water becomes more vertical and vertical lift consequently decreases. The inverse curve toward the tips of the foils provides a negative feedback to stabilise ride height.

The foil exit point is well outboard of the hull centreline so that power and horizontal area are maximised. Interference drag is minimised thanks to a local deformation in the hull.

The rudder foils are sized and angled to complement the main foils in maintaining the correct pitch attitude. To make life easier for the sailor, the foil adjustment system is designed to be simple and quick. Several combinations are possible such as getting the windward foil to pull down when sailing upwind. We are now developing a tuning manual that will narrow down the settings to a few easy to remember key benchmarks.

This is the simple explanation.

The reality is that Martin has an amazing understanding of the subtleties of this dynamic system.

My experience in aerospace allowed me to appreciate just how advanced his theories are in the numerical accuracy that is required to make them work.

The exact curvature, angle, toe-in and section shape of the foils and the geometry of the rudders as well as the hull shape are all backed up by some serious computation and, most importantly, that computation was guided by a deep understanding of the aims and constraints of the problem being solved.

– Why you decided to follow Mayfly path, as it wasn´t successful at Aarhus?

– Why you decided to follow Mayfly path, as it wasn´t successful at Aarhus?

DV: I don’t know how much our boat has in common with the Mayfly. For sure we started with a clean sheet of paper and our brief was unique.

Carbonicboats has always been about providing the best value for money to the customer. For this reason we only decided to enter the A Cat market because we could be confident to offer a high quality product that is a step ahead of the alternatives. This is reflected in the material choices, build method, styling and pricing as well as in the foil geometry.

So we adopted the latest evolution of Martin’s thinking because it proved to be the fastest solution around the track in the widest range of conditions when objectively tested using the most advanced simulation methods.

We started the project with an open mind and looked at all options in light of comparative analysis. Naturally we allocated sufficient resources to see the study through and to refine the concept once the choice had been made.

Being able to make the foils vertical for going upwind is very important. If we were stuck with maximum lift all the time, that would not be the fastest solution.

The whole boat was then integrated with the improved foil concept. For example, our hull shape could be optimised for slightly lower speeds because the foils work reliably at higher speeds.

Remember that current boats are forced to partially retract their foils in fast running conditions because if they get too much lift they are out of control. Similarly very wide sterns are more draggy than necessary but if you have an unstable foiling geometry you must have them.

Paradox was developed as a package and is distinguished by more than just the foil concept: with structural engineering by Brett Ellis (Ex Alinghi and SP Systems) and a very special construction method with spread tow carbon used in the skins, the rest of the platform incorporates significant refinements.

Custom fittings were developed for the foils and rudders so that they can work optimally and be built and installed accurately and repeatably, keeping the price competitive.

– If the platform works as intended , you think the performance gain will be definitive beyond sailor abilities?

– If the platform works as intended , you think the performance gain will be definitive beyond sailor abilities?

DV: Yes. We built the boat confident that we can offer a worthwhile gain to the customer.

– The lack of power on the As are a high wall to bare, even the Flying Phantom and the GC32 are not there right now, and they have a pretty good weight/power ratio

DV: Paradox was designed within the rule so there is no reference to other classes. Martin specified the foils to match the power available. If the boat had more power the foils would probably be bigger and takeoff might happen at a lower speed.

The aim was to beat other A Cats so that was part of the design brief. As a result our foils are not a scaled down copy of those on the Phantom or GC32. They are a custom solution that uses some of the same concepts where they will help us to go faster. At the same time some aspects are different as appropriate for the class.

The rule influences every decision: Construction aims for maximum stiffness at class minimum weight. Hull width, buoyancy and balance relate to maximum beam and minimum displacement. So it is no surprise that the foils look different to those on more powerful classes.

– You’ve done some analisys on ETNZ foil solution, what about if they race in 20knots? How do you Artemis for ie? It will be a good reference for things to come in small cats for sure

DV: The analysis I have done is only conceptual. Martin Fischer has run some numbers and his conclusions are as follows:

“I did some comparative analyses on foil setups similar to TNZ and Artemis, respectively. Both approaches have pros and cons. I think in general it is safe to say that Artemis’ approach is more upwind oriented whereas ETNZ’s approach aims to maximise downwind and reaching speed. For the A-Class this is not really relevant since with the current limitations on foils in the A-Class rules the ETNZ approach is not really feasible.”

The point I had made on our Blog (https://carbonicboats.blogspot.com.au/2012/10/rule-driven.html) is that each rule spawns its peculiar solutions and compromises.

I believe trickle-down has a place in general concepts and especially in analytical tools. Some construction methods and engineering approaches, especially in hardware and fittings, benefit greatly from the investment made at the top level (top level meaning large scale professional teams. An important distinction since each niche of our diverse sport has its champions). But one cannot look at specific hydrodynamic solutions and expect them to scale across very different sizes in very different classes.

I believe trickle-down has a place in general concepts and especially in analytical tools. Some construction methods and engineering approaches, especially in hardware and fittings, benefit greatly from the investment made at the top level (top level meaning large scale professional teams. An important distinction since each niche of our diverse sport has its champions). But one cannot look at specific hydrodynamic solutions and expect them to scale across very different sizes in very different classes.

– Do you have some pre orders already?

DV: Some yes, but we have capacity to build boats reasonably quickly so more orders are welcome.

– When do you expect to participate in a first regatta

DV: As soon as possible! We will do a couple more weeks of shakedown, basic tuning and testing.

After that we will start sailing against other boats, once we are confident all the systems work as intended.

Unfortunately many boats in our fleet are still in containers on their way back from Florida.

But as soon as they are unpacked we will be racing against them.

– Do you have plans to export?

DV: Yes, absolutely.

– People involved in the project

DV: Martin Fischer as designer and Brett Ellis as structural engineer.

The team at Innovation Composites building the major components and Carbonicboats doing machining, assembly and fitting out.

We are currently trialing test pilots and on the water support team members.

– Next steps

DV: Boat two is well underway and will be our second prototype. Customer boats will be ready in April.

The immediate goal is to prove the boat and win some races!

Longer term we will look at building masts. Again, we will only go ahead if we can identify significant gains beyond the excellent products already on the market.

Then it will be the usual development and refinement.

——–ENDS———

Copyright Catsailingnews.com

I just heard that my great sailing friend and former CEO of Hobiecat Europe has passed. May The endless oceans…

...Report was sent by an F18 Sailor, if you want Hobies reported send your own, we'll publish as usual. Cheers.

Looks like in your report the Hobies are not really present. Suggest to rewrite the article.

Thanks for the great report Wik. Great battle.

If I correctly read the results the overall winner this year is a Hobie16