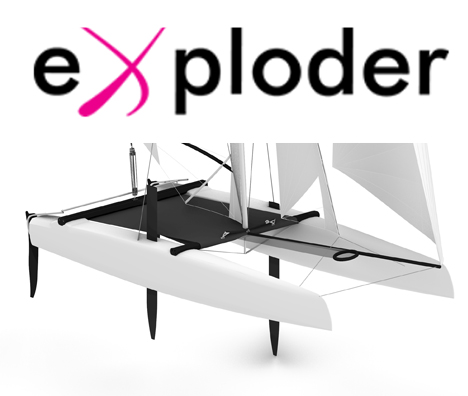

TNZ AC75 Te Aihe draft 3D Print Project (II)

Team New Zealand Te Aihe draft model & print. Model is the first version I did some months ago. Its always a good feeling seeing the lines you draw coming to a real object, being a real scale F18 or this AC75 model. I made some quick tests without much quality for the hull to see which was the best option. A vertical disposition gives the best results, the quality of the Prusa MK3 is outstanding for a 700us kit I assembled myself.

The foils were the toughest part, at this scale details are lost, so I had to modify thickness and chord length a bit on the cad file to compensate. A larger scale wont be a problem though. Also the intricate shape of thee AC75 foil arms are challenge, finally went for a one shot print with added supports.

Still need to refine foils print details and smoothness, can get them better finish, but to show the platform are good enough.

I will need to get the multimaterial kit to print with soluble print material to get best results.

Overall you can see in the pics I took some mins ago, overall quality is good for a draft print and reduced scale done at 0.20mm for the hull and .15mm for the foils . Rudder is missing, need to modify as noted on thickness as done with the foils.

There are plenty of more professional printers out here, but I can recommend the Prusa MK3 100%. Also any little issue or ways to solve printing methods there is a huge community to help out on feedback.

Next models will AC50/F50 and our Scorpion F18 and maybe TNZ A72 to get some size comparison between them.

- Printer: Prusa MK3

- Material: PLA

- Quality: 0.20mm hull / 0.15mm foils / .30mm draft for cradles

- Foils print: One Shot + supports

- Hull Print: Vertical disposition , two parts.

- Total hours print time: Around +6hs

Have you thought about printing the main foils straight then heat forming them to final shape?

Not sure if it will work but could potentially work really well.

Hi Caleb

That would be rather a sculpt, and the idea is to print the 3D cads I made. Foils a pretty accurate taking account were done from a few shots on the initial launch. The perfect solution is soluble material and the mutlimaterial kit I don’t have at hand now. But will get them better, main issue is small scale for such a special main foil shape.

Thanks for the feedback!

use a resin printer for the foils

Yes that would be the most effective, detailed and smoothest option for this scale of arms / foils, but none at hand at the moment. Prusa has launched one, will check for next investment. Thanks Bora for the tip.

Hello is it possible to get the cad files for a scale rebuild?

regards Torsten

You can check a lot of 2D plans there, unfortunately not the AC75: https://chevaliertaglang.blogspot.com/search?updated-max=2020-05-24T11:10:00%2B02:00&max-results=7

I have access to a nylon sls printer. I could run a set for you if you want. Can post process with crush walnut shell blasting.